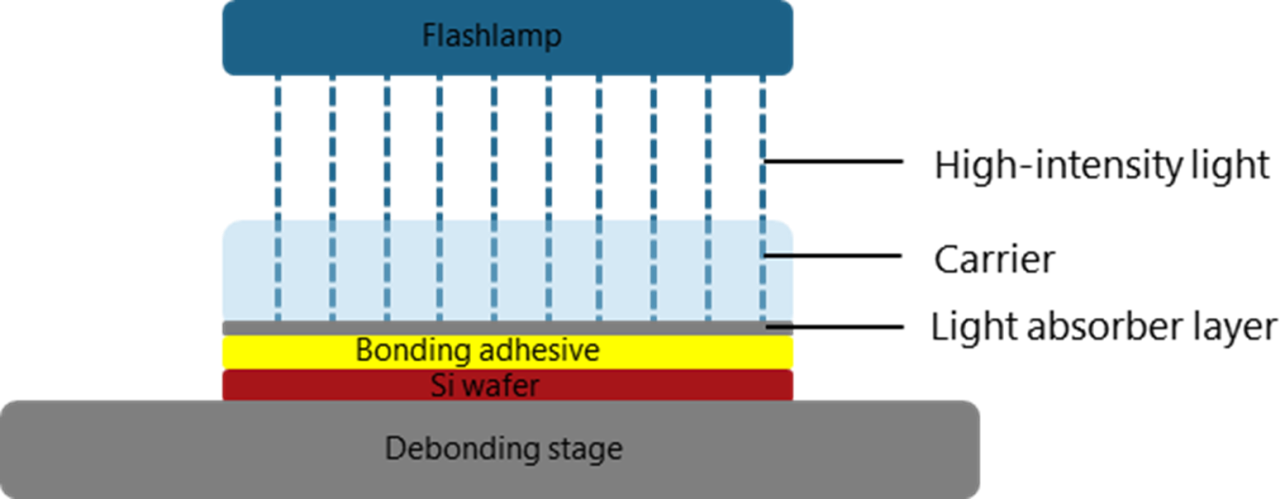

•High-intensity flashlamp source

•Light absorber converts light energy into thermal energy

•Sub-millisecond debond pulse duration

•Debond entire 150 mm wafer with one pulse

•No ash or residue

•High-intensity flashlamps to debond

•Lower processing cost per wafer by at least 30% compared to laser debond

•Cleaner debonding process – no ash or residue

•Significant reduction in cleaning efforts (financial benefit is not reflected in the 30% lower TCO)

•Reusable carriers

•Compatible with warped substrates with significant hardware changes